Sustainable waste manager Biffa and the UK arm of Austrian-based ALPLA Group, a world leader in the development, production and recycling of plastic packaging, are to work together to ensure more British recycled plastic is used in the manufacturing of UK homecare products.

From May, Biffa will provide food grade polyethylene terephthalate (rPET) plastic pellets from its recycling facility in Seaham, County Durham, to ALPLA UK. The material will be used in the production of homecare product packaging, increasing the amount of recycled plastic used in everyday household items such as washing up bottles, detergent and cleaning sprays.

The partnership is the latest development in Biffa’s strategy to create a circular economy for plastic in the UK. By replacing virgin plastic used in packaging with recycled plastic, the lifespan of plastic can become infinite when it is continually recycled and put back into packaging supply chains.

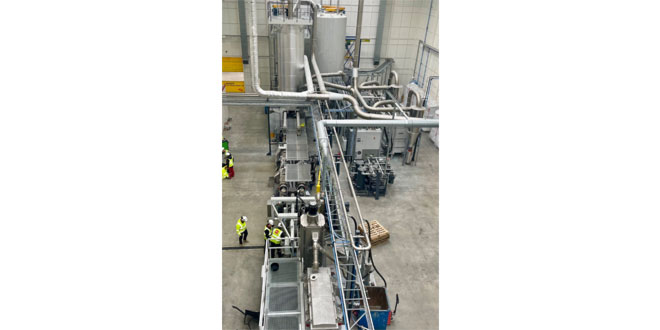

As a major UK recycler, Biffa is investing significantly in UK green recycling infrastructure, opening a £27.5m state-of-the-art plastic recycling facility last year in Seaham, which can process the equivalent of 1.3bn plastic bottles each year. By 2030, the Group has an ambitious target to quadruple its plastic recycling capacity as part of its broader sustainability strategy.

ALPLA Group announced last month to invest around €250m between now and 2025 to globalise its recycling activities in order to close the materials cycle in as many regions as possible.

Biffa will be well placed to support companies to use more recycled plastic ahead of the introduction of a tax on packaging that does not contain at least 30% recycled plastic from April 2022.

Chris Hanlon, Commercial Director at Biffa Polymers, commented:

“Biffa is a true pioneer in closed-loop recycling, turning waste plastic into materials which are a substitute for virgin plastic. Our partnership with ALPLA will contribute to our strategic ambition of a more sustainable future built around a circular economy and we’re looking forward to continuing to work with the team to achieve this.”

Tasos Pourloukakis, UK Country Managing Director at Alpla Group said, “The collaboration with Biffa goes along with our aim to push worldwide closed-loop systems on a local level. This approach guarantees the highest possible collection rates, recyclability, and quality of the materials. It also reduces the logistical effort related to our packaging solutions. It helps us to achieve the overall objective of reducing CO2 emissions and actively bringing the circular economy forward.”

Biffa has a longstanding relationship with ALPLA, and first partnered with the company in 2007 through the UK’s Dairy Roadmap, a scheme designed to unite the dairy industry’s partners to produce fully recyclable plastic milk bottles. Biffa has reprocessed over three billion HPDE milk bottles over the last decade and 85% of milk bottles in the UK now contain Biffa material.

Biffa has already worked with customers such as Suntory Beverage and Food GB&I to develop a more sustainable design of the classic 500ml ready to drink Ribena bottle using rPET plastic from its Seaham plant.