The Weidenhammer Packaging Group (WPG), Europe's leader in durable, attractively labeled consumer packaging, has completed construction work at its plant in Greece. Composite can production was launched in May in new facilities at the company's site in Inofita near Athens. Weidenhammer invested a total of €6.5 million to expand its local manufacturing capacity to meet the growing demands in Greece and throughout Southeastern Europe.

Weidenhammer started producing composite cans at its Inofita plant in 2004. The company manufactures self-opening cans for fresh dough products next door to its primary customer, the U.S. food group General Mills. Popular products sold by General Mills in these special Weidenhammer composite cans Europe-wide include Knack & Back and Pizza Crust. Weidenhammer Greece supplies several other customers with composite cans for product segments ranging from snacks and nuts, to instant beverages.

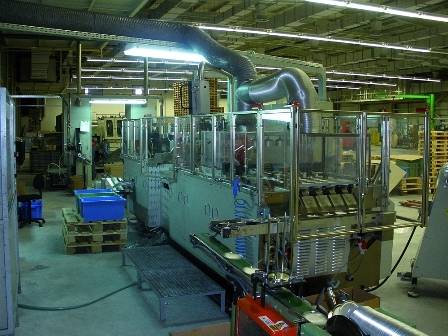

The building of the Weidenhammer production and warehouse facilities in Inofita is one of the company's largest new plant construction projects in recent years and represents a clear commitment to Weidenhammer operations in Greece. "We believe Greece has enormous market potential. It's also an ideal base of operations to supply other segments in Southeastern Europe," says Weidenhammer Packaging Group CEO Ralf Weidenhammer. The company invested €6.5 million in building the new WPG manufacturing and storage facilities in Inofita. The overall investment stems from Weidenhammer's cash flow with 20 percent subsidized through EU funds. Currently, 17 employees working on two assembly lines at the facility produce several million packages per month. The larger production facility covering 4,000 square meters offers sufficient space for future growth.

Production of new peel-off tops for composite cans was launched on a new assembly line in July. The new peel-off packaging solution was developed specifically for perishable products including baby food, powdered milk and other sensitive food applications. "In these segments, there was never a viable alternative to metal cans," explains Aris Binis, WPG Sales Director in Inofita. "Our composite cans with peel-off tops offer better sealing properties and can be used in segments where the usability of composite cans was relatively limited. In many cases, we can offer an equivalent but more competitive alternative to metal cans." The closure device is similar to the ring-pull or the tab on a metal can. Which means that consumers already know how to use it. The packaging product is also steps ahead of the competition when it comes to material and transport costs.