The era of trial-and-error manufacturing is drawing to a close, as Dassault Systèmes and NVIDIA unveil plans to combine artificial intelligence with virtual modelling to accelerate the rise of autonomous factories.

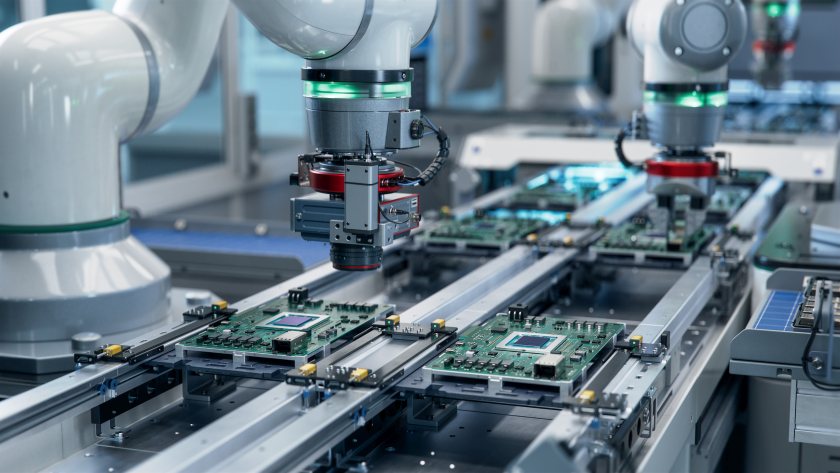

By integrating NVIDIA’s physical AI into DELMIA’s Virtual Twin technology, the companies say they are shifting industry away from rigid, pre-programmed automation towards software-defined production systems that can adapt before the first component is even made.

Manufacturers are under growing pressure. Traditional production and logistics systems are often slow to set up, ramp up or scale, while fixed automation can struggle when faced with new product variants or unexpected constraints.

Dassault Systèmes argues the answer lies in agile, modular production systems that are tested virtually before being deployed on the factory floor.

The partnership sees DELMIA providing a detailed virtual twin of production systems — a digital model that links design, engineering, manufacturing and supply chain operations. NVIDIA contributes accelerated computing and physical AI capable of simulating robotics-grade physics and perception at scale.

Together, the companies say they can allow manufacturers to validate changes in a virtual environment before implementing them in the real world, reducing risk and costly rework.

The integration of NVIDIA Omniverse physical AI libraries into DELMIA’s global production models is described as a significant step forward, enabling companies to design, simulate and operate complex systems with greater precision.

Rather than simply digitising existing processes, the collaboration aims to create a shared industrial AI architecture grounded in the laws of physics and validated scientific knowledge.

Virtual twin technology has long been used to optimise production lines, but often only after equipment has been installed. DELMIA’s approach allows entire operational ecosystems — from individual robotic cells to full factory layouts and supply chains — to be modelled and tested in advance.

Within the virtual environment, manufacturers can simulate production processes, identify bottlenecks and safety risks, optimise workflows and train operators without disrupting live operations.

The companies describe this as a shift from “mirroring reality” to “proving change”.

NVIDIA’s platform enables 3D simulations and industrial digitalisation applications, while DELMIA’s production modelling provides the operational context. AI models can assess scenarios across production constraints and variability, helping teams anticipate commissioning issues and improve flow before deployment.

The goal is to create software-defined production systems where decisions remain human-led but are supported by AI that tests and validates options in the virtual twin.

A practical example of the approach can be seen in a collaboration with OMRON, the industrial automation specialist.

By combining DELMIA’s virtual twin, NVIDIA’s physical AI and OMRON’s automation technologies, manufacturers introducing new product variants or packaging changes can simulate process logic, layout constraints and robotic behaviour before altering physical lines.

Instead of relying on trial and error, companies can test grasping reliability, conveyor orientation and downstream flow stability in the digital environment first.

Supporters of the technology argue the wider implications for manufacturing are significant.

They say software-defined production systems could unlock efficiencies by continuously identifying operational improvements, boosting throughput and reducing downtime.

Simulating processes virtually could also help companies cut waste, lower energy consumption and reduce reliance on physical prototypes, supporting sustainability goals.

Lowering the cost and risk of experimentation may, in turn, encourage greater innovation, allowing manufacturers to trial new layouts and automation strategies more freely.

Dassault Systèmes says the partnership with NVIDIA is not simply about linking two technologies, but about creating a new foundation for industrial AI.

By embedding physical AI within DELMIA’s virtual twin environment, the companies believe manufacturers will be able to build more autonomous, efficient and sustainable factories — and do so with far greater confidence.