ABB Robotics has announced the launch of three new large industrial robots – the IRB 6730S, IRB 6750S, and IRB 6760 – marking the latest expansion of its next-generation lineup.

These additions further strengthen ABB’s position as the provider of the most comprehensive industrial robot portfolio on the market, now comprising 11 robot families and 60 variants.

The newly introduced robots are powered by ABB’s advanced OmniCore™ control platform, enabling enhanced performance alongside improved energy efficiency.

According to the company, OmniCore™ delivers up to a 20% reduction in energy consumption while achieving industry-leading accuracy and speed.

“The launch of our new robots supports our vision that ‘versatility’ will be the defining factor for robotics in 2025,” said Marc Segura, President of ABB’s Robotics Division.

“This market-leading range of industrial robots and variants, coupled with our comprehensive portfolio of mechatronic platforms, cobots, and AMRs, ensures we are ideally placed to support our customers as we enter a new world of increased productivity and flexibility.

"And our automation solutions can help companies to address challenges such as labour shortages while supporting sustainable operations.”

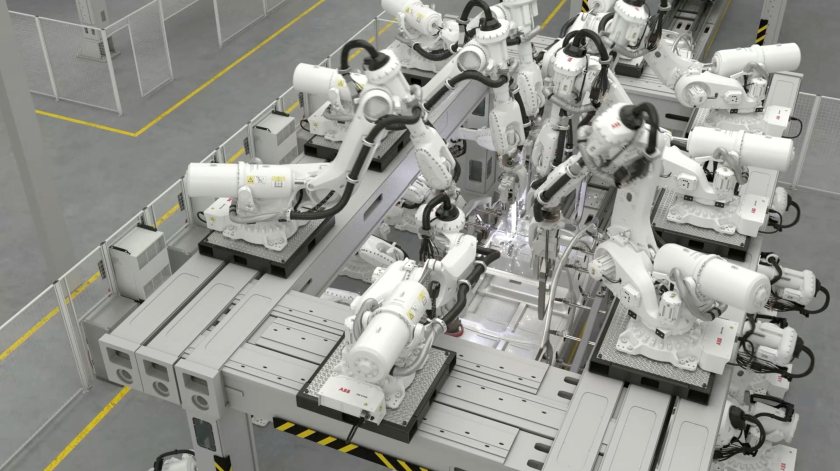

The IRB 6730S and IRB 6750S are shelf-mounted models specifically developed to increase robot density on production lines.

Capable of handling payloads of up to 350kg, they can be installed on elevated platforms or second floors and work in coordination with floor-mounted robots.

Their superior vertical and horizontal reach makes them particularly well-suited to die casting, injection moulding, and spot welding applications across industries such as automotive, foundry, construction, and general manufacturing.

Also debuting is the IRB 6760 – ABB’s highest-performing press tending robot to date. Designed for mid-sized press lines, this robot, when used with ABB’s carbon-fibre tooling boom, can achieve speeds of up to 15 strokes per minute or 900 parts per hour.

It is aimed at improving productivity in sectors such as automotive, electronics, and general manufacturing.

All three robots feature ABB’s OmniCore™ controller, which not only reduces energy use but also enhances operational precision. For instance, the IRB 6750S used in conjunction with the OmniCore™ controller can achieve path accuracy of just 0.9mm.

The new robot family has been designed with collaborative deployment in mind. ABB says that ten IRB 6730S or IRB 6750S shelf-mounted units can work seamlessly with eight floor-mounted IRB 6710~IRB 6740 models to increase spot weld counts on a car body from 70 to 80 joints in only 15 seconds – a marked improvement on previous generations.

Moreover, ABB highlights the modular architecture of its next-generation robot family as a key factor in reducing total cost of ownership.

Shared spare parts and common service tools across the range aim to streamline maintenance and lower long-term operational costs for manufacturers.

With the launch of these three models, ABB continues its strategy of delivering scalable, sustainable automation solutions to meet the evolving demands of modern manufacturing.