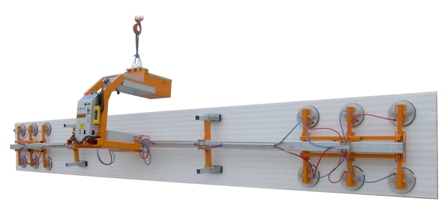

Cladding, the official provider of Wirth Oktopus cladding and roofing equipment across the UK is pleased to announce the introduction of the new Rota-King vacuum lifter for handling longer, thicker and deeper composite roof panels.

Unlike standard roofing vacuum lifters already on the market, the Rota-King has the unmatched ability to handle composite roofing panels up to 1200mm deep, 18 metres long and 400kg in weight, making it ideal to support the growing trend for longer, wider and heavier roofing panels.

Featuring 180 degree powered rotation, the Rota-King can both lift and rotate interleaved panels quickly into mounting position, helping to boost productivity on site and reduce the chances of damage to the panels themselves.

"This new vacuum lifter gives contactors the freedom to install longer panels from eaves to ridge, creating a more integral and pleasing finish to a building" comments GGR Cladding CEO Graeme Riley. "It can rotate up to 70 panels in a working day, anything up to 18 metres long and 1200mm deep, which is good news for contractors facing tight deadlines" he adds.

With more and more cladding manufacturers advocating the use of safer installation techniques, the Rota-King has distinct advantages over manual handling and can help reduce the chances of worker injury. Health and safety features of the machine include two independent vacuum circuits, each designed to handle the nominal load on its own, as well as audio-visual low vacuum alarm for extra safety.